QUALITY CONTROL STANDARDS in FURNITURE - PART 2

A case on how different internatioanl standars affect the furniture manufacturing process

Our factories in Vietnam for indoor furniture , case goods and tables; and Indonesia factory for items that related with rattan so we will give you some tips of how we are checking for the quality control for each items.

Depend on item, client, market, they will have different set of requirements, and how we manage to standardize the manufacturing process across all factories

About Indoor furniture:

It is somewhat easier to judge the quality of case goods than of upholstered items because you can see how they’re constructed.

1. Drawers:

- Drawers should fit snugly, opening and closing effortlessly.

- Drawer bottoms should slip into grooves on the drawers’ sides. The bottoms should be strong enough so they don’t give significantly when pushed down.

- Dust panels between drawers are a sign of quality, adding strength to the furniture and keeping clothes from getting snagged.

- Furniture should be constructed with stops to prevent drawers from being accidentally pulled out too far.

2. Doors, Top Lids, and Flip Tops:

- Doors and other hinged pieces should swing smoothly and quietly, close easily, and latch snugly.

- Inside of the doors should be finished.

- Insert glass panels should fit tightly so they don’t rattle.

- Long cabinet doors should hang on piano hinges running the full length (or nearly that) of the door.

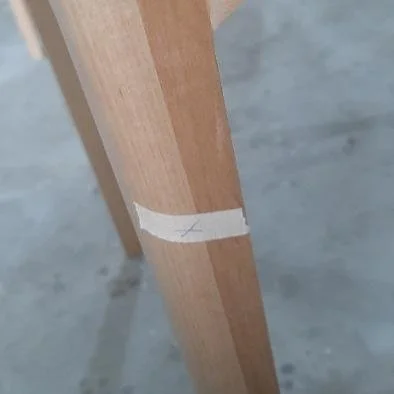

3. Legs:

- Furniture should not wobble or rock.

- In high-quality chairs, the arm and leg or back and leg are often made out of a continuous piece of wood. Legs are stronger if they’re built into the frame, too.

- Stretchers (pieces of wood connecting two legs near the floor) add strength.

- The metal leg should not have been dented, scratched.

4. Finish:

- Finish should feel smooth with no cracks, bubbles, or streaks of glue.

- Grain patterns and coloration should be similar on all drawers and doors, and should blend with other areas.

- Joints should be tight, with no visible space or filler material.

- Check whether the piece is solid wood or veneered. Cause the veneer is stuck on the MDF board so it can get discolored, and they often have weaker joints.

5. Other:

- Hardware should be substantial, smooth, and firmly bolted from the inside.

- In better cabinets, desks, and chests, the back panel is inset and screwed into place, not nailed or tacked on.

- Joints that receive stress should be strengthened with corner blocks.

- Table leaves should be easy to insert, fit flush, and match the tabletop.

- Large pieces should be fitted with leveling devices.

Many stores and manufactures have outsources production to Asia like China, Vietnam, Malaysia and other countries. This can help to lower labor cost that affect to selling price but this mean higher shipping costs, wait longer for shipping.

CERATROPIC quality control process:

Our Vietnamese factory is specializing in manufacturing furniture that made from solid wood, MDF, PB, veneer, paint, or other materials as per client request with an area of 15,000 sqm, and 200 employees. Production capacity is about 40 containers/month.

We have FSC certificate to ensure that products come from responsibly managed forests.

For both factory, we apply a similar process for quality control and that is our team will checks the quality in every production process so if there is a problem in any stage that could make the final item cannot reach the standard, our team will reject and send back to redo or destroy it.

The item that has passed the production process, it will need to pass one finally check from our team. Here are some steps that our QC team (short for Quality Control team) will check before allowing packing or loading.

In this blog, we will talk for items that we produce in our Vietnam factory.

In Vietnam factory: we have 2 types for final checking:

For fully assemble items, we are going to do 100% checking.

For knock down items, we will do 3% -10% of checking according to the agreement with the client.

1. Size and Design:

This step to check item if the design and size is correct as the drawing file.

2. Compare color with color swatch:

If item can not match 90-100% color as the approval color swatch, that item will be marked and send back to the production line to retouch color.

3. Hardware:

Our team will check for the number of hardware and if it is the right size.

4. Test:

Ceratropic Quality Control team will make some tests depending on which item to check the stability, reliability to see if the item can reach the standard. If it fails the test, we will reject it, not allow for packing and send it back to production.

Some defects TO reject

The QC team will check the raw material for durability, and moisture content…till final packing and loading on the container.

- Raw materials: our team will mark and reject deep knots, decay, split, warp…

- Structure: big gap, cracks, unbalance…

- Finishing: not clean v groove, color not same as color swatch, chipped, spot…

- Hardware: we check each item to make sure it does not lack hardware or the hardware/screw is incorrect or not functional.

Read Part three to find out how Ceratropic Quality Control team ensures quality for chair, stool, lampshade, basket with rattan, seagrass and other decorative items in Indonesia.